Winning industrial competitiveness

SunEwat is our range of BIPV glazing which integrates photovoltaic (PV) cells and thereby generates electricity. “AGC Glass Europe has been marketing SunEwat for almost ten years,” says Daphné Stassen, Project Manager at the AGC Technovation Centre. “Our in-house manufacturing model was not, by its very manual nature, able to withstand the constraints of competitiveness.”

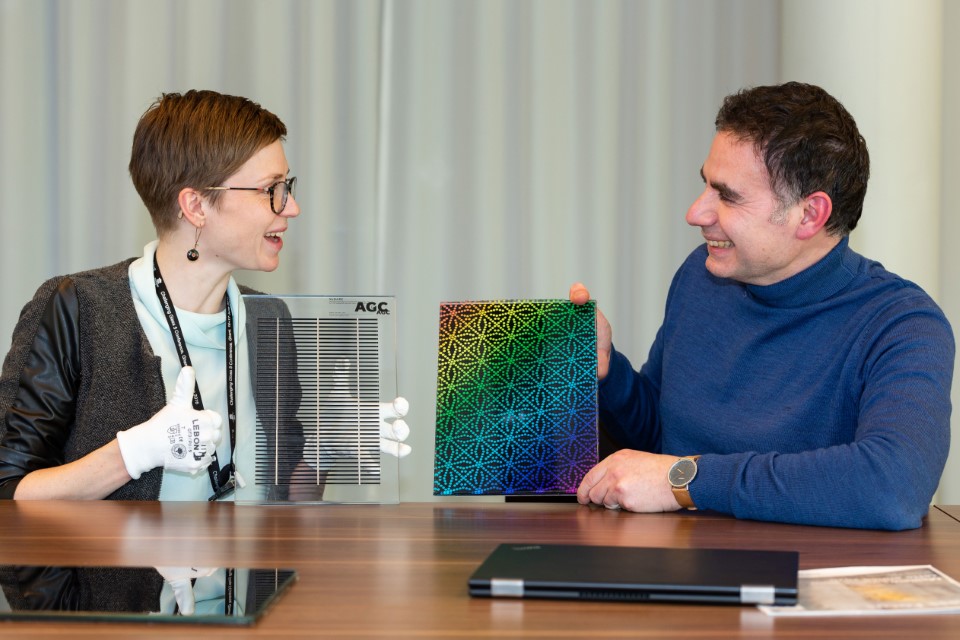

AGC has therefore formed partnerships with companies specialising in the manufacture of PV modules which produce SunEwat exclusively for its needs. This is a win-win situation according to Bassel Glore, Sales Director of Active Glass. “These partners have the necessary automated mass production lines, expertise and skills. On our side, we contribute the sales force and the knowledge of the glass and buildings industries.” In this way, AGC can now offer SunEwat solutions which, in addition to contributing to the achievement of the ZEB (Zero Energy Building), can cover their cost (payback) in less than 10 years. This is something of a novelty in the world of BIPV, a term over which we now prefer the ‘energy-generating façade’ concept.

AGC has therefore formed partnerships with companies specialising in the manufacture of PV modules which produce SunEwat exclusively for its needs. This is a win-win situation according to Bassel Glore, Sales Director of Active Glass. “These partners have the necessary automated mass production lines, expertise and skills. On our side, we contribute the sales force and the knowledge of the glass and buildings industries.” In this way, AGC can now offer SunEwat solutions which, in addition to contributing to the achievement of the ZEB (Zero Energy Building), can cover their cost (payback) in less than 10 years. This is something of a novelty in the world of BIPV, a term over which we now prefer the ‘energy-generating façade’ concept.

Transparent and opaque range

In line with current market trends, the SunEwat range has been given a strong boost with the launch of two lines: one transparent and the other opaque.

“In addition to the existing SunEwat, made up of square PV cells and renamed Square, the transparent range now also features SunEwat Stripe, the cells of which form thin horizontal stripes, offering greater transparency and a more refined aesthetic,” explains Bassel. This glazing can occupy all the “vision” parts of the building and is generally installed on roofs, louvres, canopies, carports, etc. On the other hand, the new opaque range makes it possible to use the rest of the vertical surface area of buildings for electricity generation, since it is intended for spandrels and cladding.

It features three products, all of which conceal cells while allowing the sun’s rays to pass through. “The key here is to reduce as much as possible the loss of light that impacts PV cells,” explains Daphné.

Artlite Active is laminated glazing integrating, in front of the PV cells, a pre-printed film that can depict an infinite number of designs with no colour limitations. Lacobel T Active, to be launched soon, masks the cells with a coat of paint. Its performance depends on the choice of colour. Finally, Stopray Active integrates a coating with the same optical properties (reflection, tint) as conventional Stopray glazing, while enabling the optimisation of light transmission (energy).

A SunEwat solution that is fully operated on a building covers around 50% of its energy consumption.

Market-driven development

All these developments are the result of the electronics and surface treatment (painting, coating) expertise available at the AGC Technovation Centre. “As a researcher, my role is, with the help of my colleagues in the relevant internal departments, to find solutions to the customer needs that our marketing managers report to us,” explains Daphné. “By ensuring that these solutions are achievable and industrially feasible at reasonable and sustainable costs.”

Thanks to these exclusive patented products, AGC is today the only major glass-maker to offer a complete solution, in vision glass and spandrels, for energy-generating façades. “We achieved this result by listening to the market and adapting our offering to the demand using R&D.”